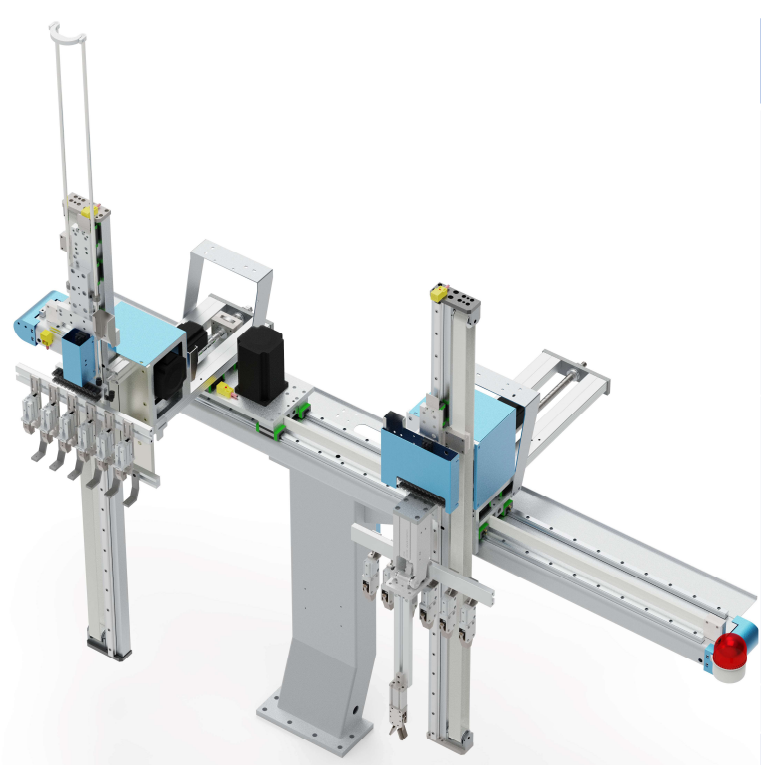

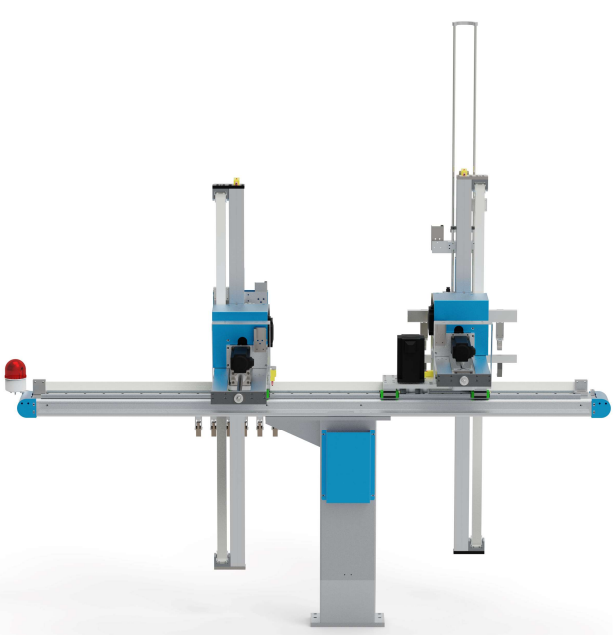

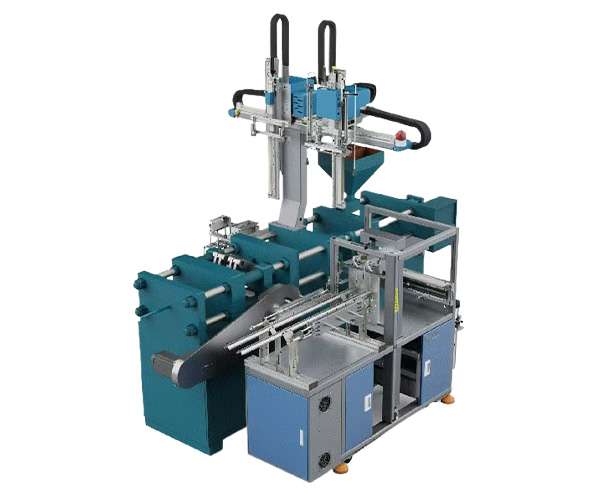

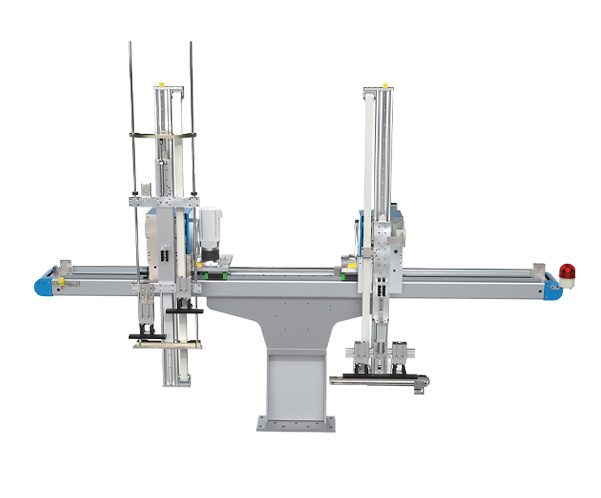

Iron-wire Inserting manipulator for flower brach injection molding

Custom production is available for wire with a thickness of 0.45-6mm and a length of 150-1000mm.

Key words:

Automation Equipment

Classification:

Artificial Plant Automation Equipment

Product Features:

1. Innovative robotic arm main mechanism, stable and efficient;

2. Patent-pending wire feeding mechanism, smooth feeding;

3. Sensitive and reliable clamps, effectively avoiding the industry problem of mold damage;

4. Fully CNC device, easy to learn and operate;

5. Customizable number of inserted wires, adjustable wire distance;

6. Customizable production: wire thickness 0.45-6mm, length 150-1000mm;

7. Various customized models with dual guiding, column insertion, etc.

Product Parameters:

Robotic Arm — Hand Injection Machine Model

| Key Parameters | Model | ||

| 1480HZ-N-500 | 1800HZ-N-650 | ||

| Robotic Arm | Maximum Width of Body | Approximately 1620mm | Approximately 1950mm |

| Effective Height of Body | Approximately 1380mm | Approximately 1700mm | |

| Maximum Height of Body | Approximately 1580mm | ||

| Minimum Clamping Depth | 165mm | ||

| Allowable mold below installation plane value | 170mm | ||

| Maximum Wire Length | 500mm | 650mm | |

| Feeder | Feeder Type | Type B | |

| Feeder Installation Method | Left Side Hanging | Hanging Frame | |

| Number of Wire Outputs | 1≤N≤4 | 1≤N≤12 | |

| Available Wire Diameter | 0.65~1.7mm (Standard Configuration) | ||

| Wire Spacing | >=28 | ||

| Wire Arrangement Method | Horizontal Linear Arrangement | ||

| Material Rack | Water Outlet Method | Clamping Water Outlet | |

| Product Material Arrangement Method | Flip ≤90° Flat | ||

| Injection Molding Machine Selection | Compatible Injection Molding Machine Type | Hand Injection Machine (Semi-Automatic Machine) | |

| Compatible Injection Molding Machine Size | Mold Capacity within 400mm | ||

Product Parameters:

Robotic Arm — Automatic

| Key Parameters | Model | |||

| 1800HZ-N-650 | 2000HZ-N-650 | 2200HZ-N-650 | ||

| Robotic Arm | Maximum Width of Body | Approximately 1950mm | Approximately 2150mm | Approximately 2350mm |

| Effective Width of Body | Approximately 1700mm | 1900mm | 2100mm | |

| Maximum Height of Body | Approximately 1580mm | |||

| Minimum Clamping Depth | 165mm | |||

| Allowable mold below installation plane value | 170mm | |||

| Maximum Wire Length | 650mm | |||

| Feeder | Feeder Type | Adjustable Spacing, Type B | ||

| Feeder Installation Method | Hanging Frame | |||

| Number of Wire Outputs | 1≤N≤12 | |||

| Available Wire Diameter | 0.65〜1.7mm (Standard Configuration) | |||

| Wire Spacing | >28 | |||

| Wire Arrangement Method | Horizontal Linear Arrangement | |||

| Material Rack | Water Outlet Method | Clamping Water Outlet, Scraper Water Outlet | ||

| Product Material Arrangement Method | Flip ≤90° Flat | |||

| Injection Molding Machine Selection | Compatible Injection Molding Machine Type | Fully Automatic Machine | ||

| Compatible Injection Molding Machine Size | Body Width <1000 | |||

Common Robotic Arm Models:

| Model Type | Injection Molding Machine Model | Number of Wire Outputs | Model | Non-Standard Customization | Crossbeam Type |

| Robotic Arm | Hand Injection Machine (S) | 2 Pieces | 1400HZ-2-500 | Dual Guiding (SD), Three Plate Mold (SBM), Rotating + Material Pushing (BL), Column Insertion (LC) Increased Stroke, (850/1000), 12 or more Large Plate Clamps (BJ) | Standard Crossbeam |

| 4 Pieces | 1400HZ-4-500 | ||||

| 6 Pieces | 1800HZ-6-650 | ||||

| 8 Pieces | 1800HZ-8-650 | ||||

| 10 Pieces | 1800HZ-10-650 | ||||

| 12 Pieces | 1800HZ-12-650 | ||||

| Automatic Machine (2) | 4 Pieces | 1800HZ-4-650 | |||

| 8 Pieces | 1800HZ-8-650 | ||||

| 4 Pieces | 2000HZ-4-650 | ||||

| 8 Pieces | 2000HZ-8-650 | ||||

| 10 Pieces | 2200HZ-10-650 | Wide Crossbeam | |||

| 12 Pieces | 2200HZ-12-650 | ||||

| 14 Pieces | 2200HZ-14-650 | ||||

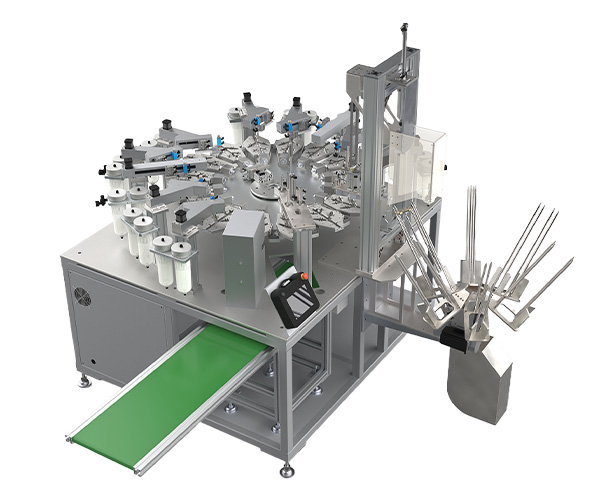

| Automatic Machine (Z) | 24 Pieces | 2200BJ-24-650 | / | Wide Crossbeam | |

| Hand Injection Machine (3) | 24 Pieces | 2200BJ-24-650S | With Mold Opening System | ||

More Product

Automatic PE Branch Injection Molding and Yellow Core-line PaintingSystem

Unit Style PE Branch Yellow Core-line Painting Machine

Rotary Style Automatic Yellow Core-line Painting Machine

Automatic PVC Branches Cutting Machine

Semi-Automatic Branch Binding Machine

Hot Forging Manipulator

Row injection molding manipulator

Five-axis servo robotic arm

Single-arm robotic arm

Request a Quote Today

Reach Us

Location :

Huizhou YinHua Technology Co., Ltd. 6th Floor, Building A2, No. 8-4 Yuanhui Road, Chenjiang Street, Zhongkai High-tech District, Huizhou

Email :

anticqhf597@gmail.com

Phone :

0752-3279196