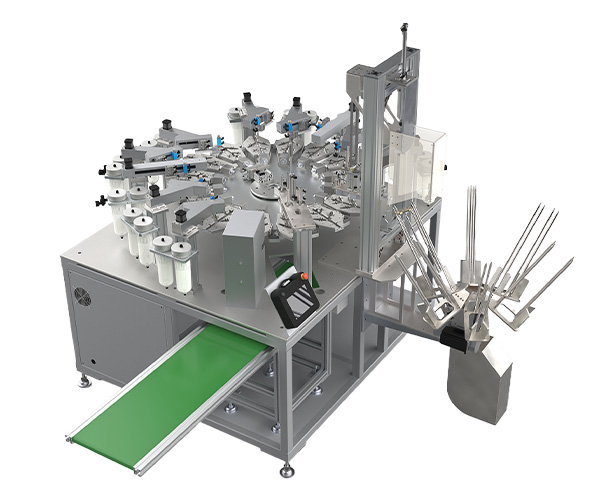

Used in conjunction with injection molding robots to achieve integrated production of pine branch injection molding and yellow core production.

Highly automated: The equipment achieves semi-automatic feeding of Christmas tree PE leaves, fully automatic discharging, automatic yellow core punching, automatic wave pattern pressing, and automatic product flipping.

Custom production is available for wire with a thickness of 0.45-6mm and a length of 150-1000mm.

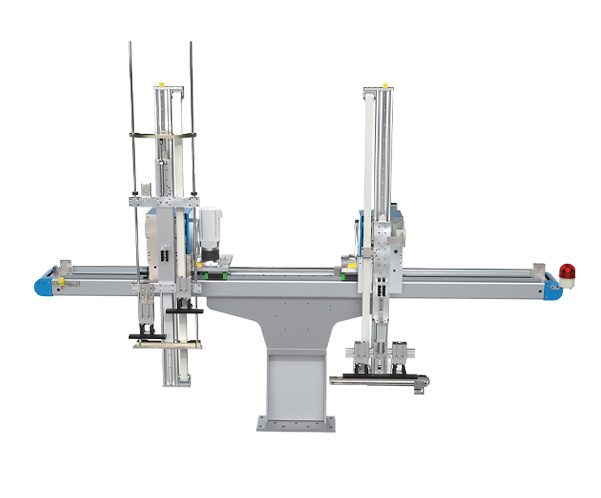

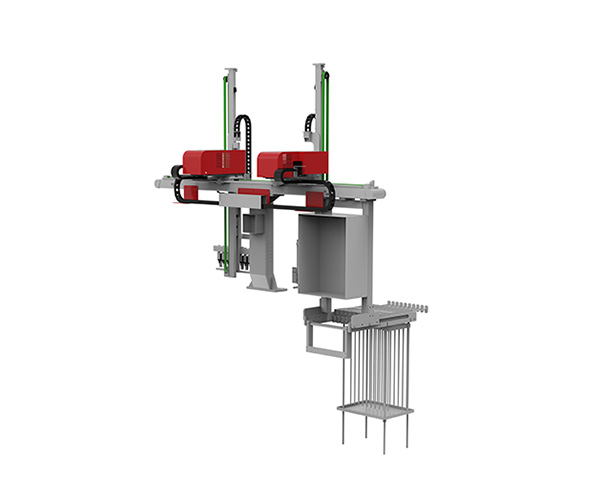

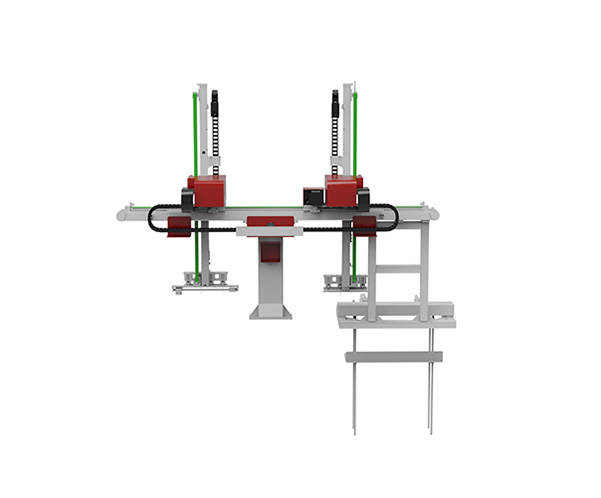

2-hand robot arm

This 2-hand equipment offers efficient dual-arm operation, significantly reducing labor costs while doubling production efficiency. It ensures consistent and uniform painting quality for every leaf, making it an ideal choice for customers seeking a cost-effective and reliable solution for small to medium-scale production.

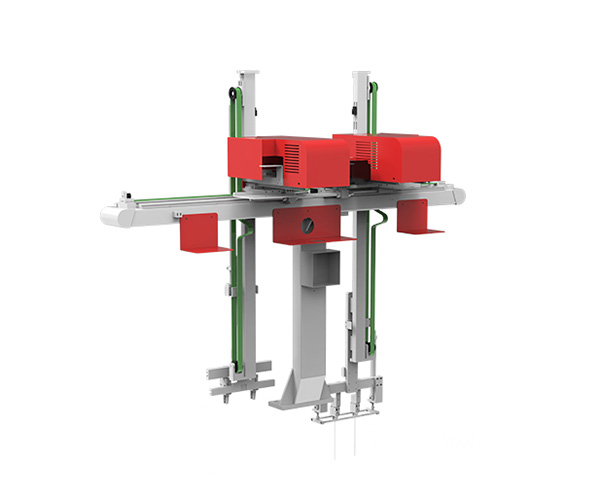

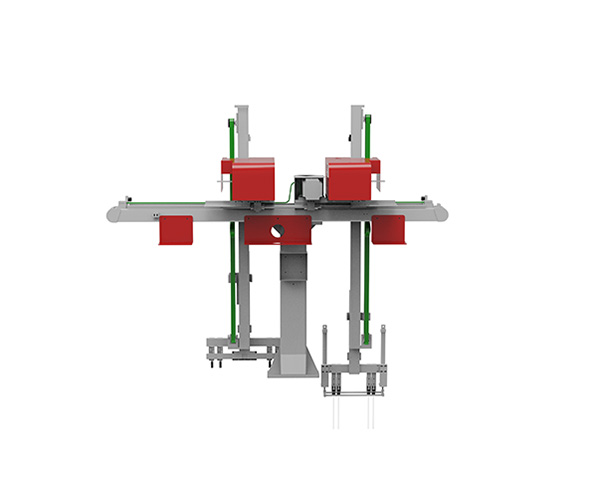

4-Hand Robotic Machine

With four mechanical arms working in tandem, this equipment provides high-speed and efficient leaf painting, ideal for medium to large-scale production. It maximizes production yield and ensures stable quality with uniform paint application, helping customers achieve higher efficiency and profitability.

Featuring ten mechanical arms, this high-capacity equipment is designed for large-scale production. It delivers exceptional efficiency and consistent quality, reducing labor costs and increasing overall production capacity. This powerful solution is perfect for customers aiming to boost productivity and meet high-volume demands.

robot arm with 2 to 60 hands

This versatile equipment offers a wide range of configurations from 2 to 60 hands, allowing customers to customize their production capacity according to specific needs. It combines high efficiency, consistent quality, and flexibility, making it an excellent choice for both small-scale and large-scale production, ensuring optimal performance and cost savings.