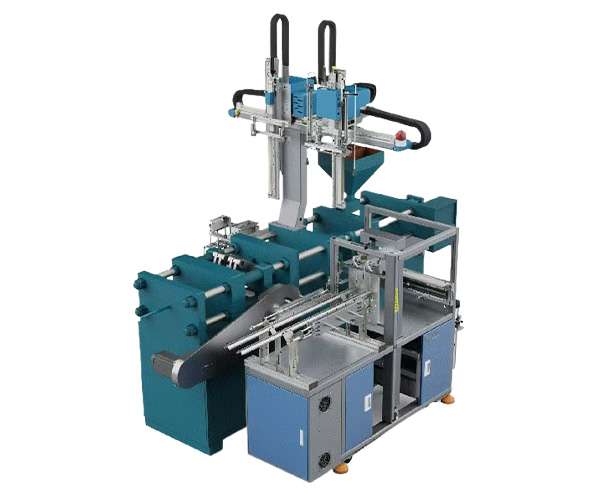

Fully Automatic PE Leaf Injection Molding Yellow Core System

Used in conjunction with injection molding robots to achieve integrated production of pine branch injection molding and yellow core production.

Highly automated: The equipment achieves semi-automatic feeding of Christmas tree PE leaves, fully automatic discharging, automatic yellow core punching, automatic wave pattern pressing, and automatic product flipping.

High-precision sensors detect the servo cutter, ensuring stable quality. A single shift saves approximately 60,000 liters of high-pressure air (compared to semi-automatic systems).

High safety: Automatic sorting and conveying of iron wires from 6 to 27 inches, with the mechanism set inside the chassis, preventing injuries caused by the iron wires popping out due to poor bending during transportation.

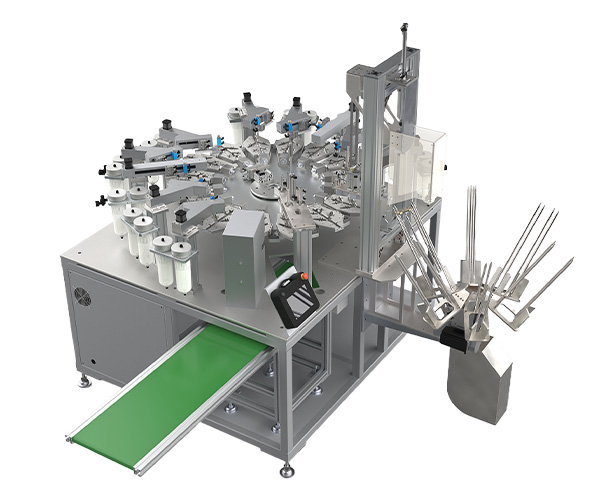

The fully automatic Christmas tree leaf painting equipment helps customers reduce labor costs, improve product yield, and enhance production efficiency by automating the painting process with high consistency and speed, delivering high-quality results.